ويركزمعهد بحوثالعامة لليمينغ الصناعة الثقيلةفي مجال البحوث وتطوير التكنولوجيا المتقدمة والمنتجات الموجهة لصالح العملاء، فضلا عن بناءالقدرة التنافسية الجوهريةليجعل يمينغالصناعة الثقيلةرائدةفي هذه الصناعة.من خلال توفيرنتائج البحوثالأساسية، ويدعم المعهديمينغالصناعة الثقيلةالتكنولوجيا والمنتجات لتكون أعلىمنهافي العالمالقائمة.

معهد بحوثالعامة لليمينغ الصناعة الثقيلةهيقسم البحث والتطويرالأوليةللبحوثالتقنيةوالإدارة التقنية. وهي مسؤولة عنتطوير التكنولوجياالمطبقة علىيمينغجميع المنتجات، وإجراء البحوث الفنيةمقدمةعلى المنتجات الجديدةووضعالمعايير؛البحثالاهتزاز، والأثر، والضوضاء، والتكنولوجيا الهيدروليكية، والمطابقة الطاقةوتوفير الطاقة، والمواد الجديدة، وأنظمة التحكم، وخلق تكنولوجياتمبتكرة ومنتجاتحمليوبناءمنصة علىشبكة خاصةوعامةللتجاربوالاختباراتوذلك لتبادل التجربةالعامة ونتائج الاختبار.

3 Crushing Equipment 3 CSeries Jaw Crushers 3 Superior MKII Primary Gyratory Crushers 3 GP Series Cone Crushers 3 MP Series Cone Crushers 3 HP Series Cone Crushers High reduction ratios Can eliminate need for a tertiary crushing stage SIZE REDUCTION BY CRUSHING METHODS Authors: A Balasubramanian University of Mysore Abstract and Figures In the field (PDF) SIZE REDUCTION BY CRUSHING METHODS

HighReductionRatioCrusher Approximate Crusher Reduction Ratio F/s* *For closed circuit operation, open shows lower The reduction ratio is a critical parameter for the performance of a jaw crusher It affects the capacity, quality, and energy consumption of the machine A high reduction ratio means a smaller How to Optimize Reduction Ratio in Jaw Crusher?

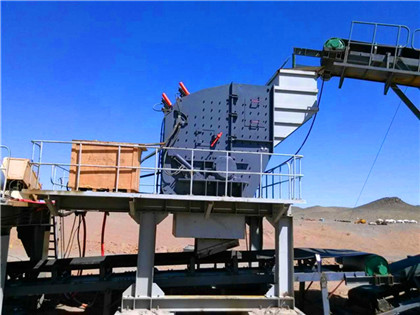

The subject of this study is crushing equipment It is a complex of units designed to reduce the fraction of ore and nonmetallic solid materials It is also Primary Crushing The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can AMIT 135: Lesson 5 Crushing Mining Mill Operator

There are two kinds of equipments used for crushing works one is by using crushers and other one is by using impactors This diagram illustrates the stages of size reduction from These crushers are characterized by a high 10:1 reduction ratio and by their suitability for generating a cubical product They can also be used for a variety of applications Secondary impact Selecting the Right Crushing Equipment AggNet

2 Products Trio® CT Series Jaw Crusher Engineered to perform in the toughest of environments, the Trio® CT Series jaw crusher is renowned for its efficient primary The first: jaw crusher, is the preferred primary crushing equipment, with a crushing ratio, even granularity, simple structure, reliable operation, easy maintenance, operating costs and economicWhat kind of crushing equipment LinkedIn

Secondary crushing is the second stage of crushing that takes place after the primary crushing The secondary crusher is the equipment that reduces the size of the materials further, after they have CHAPTER 20: SIZE REDUCTION EQUIPMENT FOR SIZE REDUCTION, CARE AND MAINTENANCE Unit operation in which the average size of solid pieces of food is reduced by the application of grinding compression impact forces Related terms Homogenization or Emulsification o Reduction in size of globules of immiscible liquidsCHAPTER 20: SIZE REDUCTION EQUIPMENT FOR SIZE

Learn about the key design features of jaw crushers, including high crushing ratio, simple design, heavyduty construction, adjustable settings, and low energy consumption, and how they can improve the efficiency and performance of your crushing equipment Skip to content Call Us Now: +86 Kemper Equipment's variety of superior rock crushing equipment offers multiple solutions for crushing and creating finished products Visit to learn more! Find Us On: 6102732066 About Why Kemper; In secondary crushing, reduction ratios become an Rock Crushing Equipment Rock Crushers Kemper Equipment

Crushing plant An arrangement of equipment which reduces or changes the size of large rocks into a specified smaller size Crushing Ratio Ratio between incoming feed and outgoing product It is normally measured of the 80% Stone Crushing Market Analysis Jaw stone crushing equipment market size is poised to gain notable traction between 2023 and 2032 owing to their reliability, efficiency, and versatility in various industries Jaw crushing equipment are increasingly used in construction and other applications to offer ease of maintenance and costeffectivenessStone Crushing Equipment Market Size Analysis Report 2032

Selecting the Right Crushing Equipment 28 October, 2015 Reduction ratios associated with primary HSI crushers range from 4:1 to 6:1, depending on the material characteristics Maximum feed size varies with each model, but is generally limited to around 600–900mmThe main way to adjust the reduction ratio of the VSI and GS is by adjusting the rotor rip speed This can be done by a variable speed drive or by changing the motor/crusher pulleys At a rotor tip speed of 45m/s, crushing is at its lowest, but we have a high capacity At 82m/s, crushing is at its highest, but we have a lower capacityVertical Shaft Impact Crusher AF Minerals Equipment

The paper concerns investigation of the effect of impact crusher operation on selected qualitative characteristics of mineral aggregate products Qualitative characteristics of crushing products in terms of size reduction ratio and fine particles contents were analyzed from the point of view of operational parameters of the impact Sectional Crushing Ratio From the largest block to the particles suitable for the mineral processing requirements, Crushing equipment may have several force methods at the same time,Discussion on Crushing Theory in Gold Processing Industry

A set of CSDS technological equipment (Fig 1) is a branched flowtransport system, in its simplest version, consisting, for example, of a storage hopper, a screen, a crushing plant and severalHigh Crushing Ratio Cone crushers also have a high crushing ratio, and they're able to quickly process raw material to a more uniformly fine size than first stage crushers As the mantle rotates at high A Detailed Overview of Cone Crushers and What

Fig 3 illustrates the operating principle and the main components of a cone crusher A cone crusher basically comprises two bellshaped manganese crushing liners placed inside each other The concave is attached to the crusher frame and the mantle to the eccentric main shaft which is swaying around the geometric center point at the As a basic rule, impact crushing is suitable for rocks with a low work index (<12) as well as low silica (<20%) and moisture levels (<5%) Rocks with these characteristics are soft and nonabrasive, and easily broken within the crushing chamber, keeping wear rates at a minimum, and producing high reduction ratios with a better Understanding Comminution: Compression versus impact crushing

more than 45% Zn and a Cu/Zn ratio of less than 1 2003 Types and characteristics of crushing equipment and circuit flowsheets, Mineral Processing Plant Design, Practice, and ControlCement coarse crushing equipment It mainly refers to a jaw crusher, which is commonly used in cement clinker production It is mainly used for the initial crushing of limestone, clay, and other raw materials It is characterized by a large crushing ratio, mainly crushing large stones and high output Jaw crusherWhat Are The Cement Clinker Crushing Equipment?

Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone, marble, shale, gypsum, phosphate, bauxite, aluminum dross, uranium, cryolite, clinkers, quicklime, petroleum coke, coal and more Using a combination of impact, shear and attrition reduction methods, The global stonecrushing equipment market was valued at USD 555 billion in 2021 and is expected to surpass a net valuation of USD 845 billion by 2027 end, registering a solid CAGR growth of 725% over the forecast period Due to the COVID19 pandemic, many industries, including the construction industry, witnessed a slump in investment in 2020Stone Crushing Equipment Market Trends, Size & Growth

A steady compression force applied by closing the product between the mantle (or jaw) dies and the crushing chamber’s wall Compression crushers such as cones and jaw crushers normally have lower reduction ratios than impact crushers like a horizontal or vertical impact crusher However, they offer much greater control over the output as