ويركزمعهد بحوثالعامة لليمينغ الصناعة الثقيلةفي مجال البحوث وتطوير التكنولوجيا المتقدمة والمنتجات الموجهة لصالح العملاء، فضلا عن بناءالقدرة التنافسية الجوهريةليجعل يمينغالصناعة الثقيلةرائدةفي هذه الصناعة.من خلال توفيرنتائج البحوثالأساسية، ويدعم المعهديمينغالصناعة الثقيلةالتكنولوجيا والمنتجات لتكون أعلىمنهافي العالمالقائمة.

معهد بحوثالعامة لليمينغ الصناعة الثقيلةهيقسم البحث والتطويرالأوليةللبحوثالتقنيةوالإدارة التقنية. وهي مسؤولة عنتطوير التكنولوجياالمطبقة علىيمينغجميع المنتجات، وإجراء البحوث الفنيةمقدمةعلى المنتجات الجديدةووضعالمعايير؛البحثالاهتزاز، والأثر، والضوضاء، والتكنولوجيا الهيدروليكية، والمطابقة الطاقةوتوفير الطاقة، والمواد الجديدة، وأنظمة التحكم، وخلق تكنولوجياتمبتكرة ومنتجاتحمليوبناءمنصة علىشبكة خاصةوعامةللتجاربوالاختباراتوذلك لتبادل التجربةالعامة ونتائج الاختبار.

1 Introduction Metallic smallscale mining (SSM) in Chile is devoted to mainly copper, gold and silver Most SSM producers are concentrated within the A review of the copper reserves in million tonnes of copper and the copper ore grades (percentage of copper) using the latest data Processing of Complex Materials in the Copper Industry:

In this Special Issue, recent advances in copper ore processing and extraction are discussed, focusing on: innovations in hydrometallurgical, Based on the results of the overview, a future processing plant is predicted to use ∅128–13 m SAG mills, HPGRs with the roll diameter of 3 m, vertical Designs of new operating copper processing plants: process types

Copper processing Ores, Refining, Smelting: Principal forms in which copper ores are found include native copper, porphyry copper, massive deposits, and mixed ores Native copper is simply the metal found Besides froth flotation, leaching is the second most common method to process copper ore Leaching can be carried out via conventional sulfuric acid leach or with support of bacteria An overview Processing Tests, Adjusted Cost Models and the

There are two big opportunities for DES in copper processing: first, the processing of copper deposits in jurisdictions with water usage sensitives and, second, the For copper mining, fuel consumption increased by 130% and electricity consumption increased by 32% per unit of mined copper in Chile from 2001 to 2017, Transparency on greenhouse gas emissions from mining

Acid Leaching Copper Ore Treatment Method The treatment of copper ores, both oxides and sulfides by means of flotation, hydrometallurgy or other processes has been well established for many years Flotation has been applied generally to the treatment of sulfide ores, both in small and large scale operationsCopper is an essential material in numerous industries and the third most used metal in the world, after iron and aluminium It is widely used in many applications in industry as well as in healthcare [1,2,3]Since the beginning of the 20th century, the use of refined copper has grown by approximately 34% annually—from less than 05 million Moisture Determination for FineSized Copper Ore by Computer

“The equipment needed are excavators, dump trucks and front end loaders which small scale miners can always outsource through hiring and buying theirs after few cycles since its highly remunerative A In this investigation, a laboratoryscale study to extract copper (Cu) from its oxide ore (0425–112 mm particle size) was conducted using varied sulfuric acid (H2SO4) concentrations (005–05 M) as a lixiviant Through a physicochemical and mineralogical analysis of real field ore samples from the Almalyk mine heap site Copper Extraction from Oxide Ore of Almalyk Mine by H

By the early 1900s the company had resorted to smallscale chemical leaching of lowgrade ores and tailings, with copper recovery by the cementation process This phase of mining ceased in 1907That’s where Australia can help We have the world’s largest supply of four critical minerals: nickel, rutile, tantalum and zircon We’re also in the top five for cobalt, lithium, copper, antimony, niobium and vanadium Even better, many of these minerals can be produced as a side benefit of mining copper, aluminiumcontaining bauxiteAustralia’s yet to capitalise on its rich deposits of critical

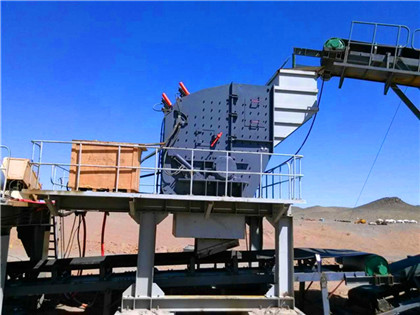

The copper ore processing production line has the advantages of high efficiency, low energy, high processing capacity, and reasonable economy Copper ore processing equipment selection principles When selecting equipment, it must meet the requirements of its dressing plant scale, equipment form, ore properties, and process flowGREEN MINING TECHNOLOGY FOR THE SMALLSCALE MINING INDUSTRY The Philippines is fifth of the most mineralrich countries in gold, copper, nickel, and chromite and ranks 22nd in the world’s gold producing countries in 2017 Mining industry in the Philippines generated and contributed billions of pesos to the national economy in terms GREEN MINING TECHNOLOGY FOR THE SMALLSCALE MINING

Producers, however, are facing challenges due to falling head grades and more complex ore mineralogy In this Special Issue, recent advances in copper ore processing and extraction are discussed, focusing on: innovations in hydrometallurgical, pyrometallurgical, electrometallurgical, and preconcentration technologies; improving In the crushing process of copper ore processing, the twostageclosedcircuit crushingsinglestage ball milling process is more common in small copper ore concentrators whose production scale is below 500t/d Threestage crushing is currently the most crushing and grinding process used by large and mediumsized copper ore Copper Ore Production Process JXSC Mineral

Copper is by value one of the main mineral commodities in the world Due to the nature of mineral deposits, not only ore minerals are extracted, but also barren minerals that have to be deposited as tailings 21 Overview and Industrial Applications Leaching is defined as “the treatment of complex substances, like a mineral, with a specific solvent, able to separate its soluble parts from the insoluble ones” The process is used for the production of a concentrated solution of valuable solid material or to remove an insoluble solid from a Copper Mineral Leaching Mathematical Models—A Review

One solution is to be able to process copper sulphide ores hydrometallurgically However, it is widely known that sulphide copper ores—and chalcopyrite in particular—have very slow dissolution kinetics in traditional leaching systems An alternative to improve the extraction of copper from sulphide ores is the use of a Leaching of copper, cobalt (a) and iron (b) from the copper oxide ore under optimal experimental conditions (077 M H 2 SO 4,5 g of ore, particle size: 80%À6223 mm, S/L: 13%, Figures(PDF) Leaching kinetics and predictive models for ResearchGate

the first largescale copper SX plant in the world, commissioned in 1974 this region is characterised by a large number of small (3 to 20 kt/a) plants, mainly Chineseowned, and a few very large (>200 kt/a) plant was redesigned and expanded to process oxide ore from the Lonshi deposit, which was located in the DRC, some 35 km awayCopper Content in Ores and Concentrates A global copper minebymine review undertaken by ICSG found that the global average copper ore grade was as low as 045% copper in reported reserves and only 065% copper in 2015 copper mine production Global weighted average of copper concentrate output in a large sample of Processing of Complex Materials in the Copper Industry:

In this investigation, a laboratoryscale study to extract copper (Cu) from its oxide ore (0425–112 mm particle size) was conducted using varied sulfuric acid (H2SO4) concentrations (005–05 M) as a lixiviant Through a physicochemical and mineralogical analysis of real field ore samples from the Almalyk mine heap site The process of mineral concentration and cleaning was conceptualized centuries earlier by selective hand sorting of desired or undesired particles of lumpy size by mere appearance, color, texture, heaviness, etc Hand sorting was common practice to separate rich ore as concentrate and wood or iron pieces as a cleaning process from Small Scale Mining an overview ScienceDirect Topics

Flotation is usually used by large scale miners but can also be applied in small scale operations It is a process that works best for processing complex ore types, especially ores that are difficult to process using gravity methods In flotation, a mixture of slurry (crushed ore and water) and frothing agents are added into a flotation machineCopper Flotation Technology for Small Scale Mining Department of Mining, Metallurgical, and Materials Engineering College of Engineering, University of the Philippines PROCESSING DIWALWAL Gold Ore BICOL Gold Ore BAGUIO Gold Ore PROCESS FLOW Tails CONCENTRATE ORE DIWALWAL Gold Ore 200 µm 100 µm gold pyrite ECOFRIENDLY Recovery of GOLD and COPPER for the SmallScale