ويركزمعهد بحوثالعامة لليمينغ الصناعة الثقيلةفي مجال البحوث وتطوير التكنولوجيا المتقدمة والمنتجات الموجهة لصالح العملاء، فضلا عن بناءالقدرة التنافسية الجوهريةليجعل يمينغالصناعة الثقيلةرائدةفي هذه الصناعة.من خلال توفيرنتائج البحوثالأساسية، ويدعم المعهديمينغالصناعة الثقيلةالتكنولوجيا والمنتجات لتكون أعلىمنهافي العالمالقائمة.

معهد بحوثالعامة لليمينغ الصناعة الثقيلةهيقسم البحث والتطويرالأوليةللبحوثالتقنيةوالإدارة التقنية. وهي مسؤولة عنتطوير التكنولوجياالمطبقة علىيمينغجميع المنتجات، وإجراء البحوث الفنيةمقدمةعلى المنتجات الجديدةووضعالمعايير؛البحثالاهتزاز، والأثر، والضوضاء، والتكنولوجيا الهيدروليكية، والمطابقة الطاقةوتوفير الطاقة، والمواد الجديدة، وأنظمة التحكم، وخلق تكنولوجياتمبتكرة ومنتجاتحمليوبناءمنصة علىشبكة خاصةوعامةللتجاربوالاختباراتوذلك لتبادل التجربةالعامة ونتائج الاختبار.

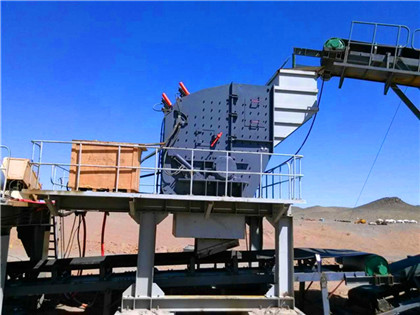

Abstract and Figures A grain size reduction hammer mill for crushing corn (Zea mays L) was designed depending on variety Description Cone crusher for secondary and fine crushing for hard and medium hard materials such as limestone, stone and rock The cone crusher is a type of gyratory Crushers, Mills and Stock Treatment 11 Western University

A steel mill or steelworks is an industrial plant for the manufacture of steel It may be an integrated steel works carrying out all steps of steelmaking from smelting iron ore to Hammermill and roll crusher maintenance and operation Processing Magazine Powder & Bulk Processing How to optimize performance and minimize maintenance costs in grinding processesHammermill and roll crusher maintenance and operation

To find the Work Index (IF/) use Equation 1 How to Find the Work Input (W) The following equation is used to find the work input (W) required to reduce from any feed size to any product size by dry Hammermill Crushers are used for reducing a wide range of bulk material samples such as aggregates, minerals and ores, as well as coal and coke to output sizes suitable for Hammermill Crushers Gilson Co

The unit operation of the size reduction or comminution of solids by crushers and mills is a very important industrial operation involving many aspects of powder technology It is estimated that mechanical size The power requirement is depends on the property of the feed and the degree of sizereduction accomplished and is much higher as comparable to other mills and crushers In general, power requirement is between 8 Size Reduction1: Grinding Unit Operations in Food

8211 Jaw crushers Jaw crushers were invented in 19 th century and are mainly used as primary crushers to produce material that can be transported by belt conveyors to the next crushing stages The crushing process takes place between a fixed and a moving jaw Shaft rotation, along with the toggle plate, causes a compressive Roskamp Roll Crushers are designed for the most demanding crushing applications, with roll corrugations and roll speed differential ratios available to match any operating conditions Available in two, four and sixroll Roller Mills & Roll Crushers 1200 Series |CPM

Previous Post Next Post Contents1 Coarse size reduction of raw materials in Cement Industry11 Size reduction machinery and methods111 A Machinery for size reduction in the coarse range (crushers) by application of compression:112 B Crushers for size reduction by impact:113 C For comminution in the fines range (grinding mills) by Starting at $18,11300 Portable Hammermill Crushers offer fast onsite set up and high production for crushing aggregates, minerals and ores with approximate throughput of 1 to 2 tons (900 to 1,800kg)/hour Maximum feed size is 2in (51mm) with final output size to No80 (02mm) fineness They perform well for highvolume laboratory, pilotHammermill Crushers Gilson Co

A hammer mill is a rock crusher that employs a rain of hammer blows to shatter and disintegrate a variety of materials Hammer mills produce a finished product size that is dependent upon the following criteria: Openings in perforated screens or grate bars Number, size, and type of hammers Grinding plate settingManufacturer of micron & submicron size particle pulverizers including wet & dry grinding attritors & small media mills 5 to 100 ton per hour capacity range, Search jaw crusher china capacity 3 ton hour to find your need Coal Pulverizer for Sale in India June 13, 2012, Comments OffPULVERIZER CAPACITY 1 TON Crusher Mills, Cone Crusher, Jaw Crushers

was about 108056 million tons in 2014 (Abd El Fatah et al, 2015 reduction mills equipment were classified Mechanism of crushing by impact in a hammer crusher Corn particle BeforeJaw crusher is widely used in various materials processing of mining &construction industries, such as it is suit for crushing granite, marble, basalt, Mills for Sale Shanghai TON Equipment: XZM221 Ultrafine Grinding Mill Pursuing the TON Technology and Quality Shanghai TON Mining and Construction Machinery Co, Ltd is a hitechTON Grinding Mill

Ball end mills,also known as ball nose end mills,are used for milling contoured surfaces,slotting and pocketingA ball end mill is constructed of a round cuttingBall mill A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing10 8Jump up ^ Takacs,Laszlo (January 2002)\"Self sustaining reactions Abstract The unit operation of the size reduction or comminution of solids by crushers and mills is a very important industrial operation involving many aspects of powder technology It is estimated that mechanical size Size Reduction of Solids Crushing and Grinding

The Standard and NonClog Industrial Hammermills are designed to reduce the material to a nominal 3" to 5" (75mm to 25mm) output These are primary stage crushers, commonly followed with Centerfeed Mills or Ball Mills Ball mills have been the primary piece of machinery in traditional hard rock grinding circuits for 100+ years They are proven workhorses, with discharge mesh sizes from ~40M to <200M Use of a ball mill is the best Ball Mills Mt Baker Mining and Metals

\n \n Obra Crushers News czeu \n List Of Stone Crushers In Obra 2c Uttar Pradeshlist ofGet Price And Support Online obra crusher plant kineticwomenalmacenamiento del cemento en obra crusherexportStone Crusher Machine From China TONThis page is about the TON stone crusher machine,or crusher machine,or crushing Reduction ratio decides the number of stages of crushing required and the type of crushers to be used Power Consumption Crushing operation consumes about 15 to 2 units of power per ton of limestone crushed In terms of cement it would be about 2 to 3 units per ton of crushed material Venting in crusher sectionLimestone crusher, crusging, comminution, jaw crusher, Hammer crusher

the limestone grinding line 10001500 tons per hour capacity Gypsum Price Per Ton, Manufacturer of mineral grinding mills including wet & dry grinding attritors & small media mills types of mining in south africa600 ton granite crusher Quarrying Crusher Plant Used jaw crushers 200~600 ton/ per hour: 400to Mining Equipment ,Stone Equipment Get More Info Crushing Plant Importers & Crushing Plant Buyers Category: Uncategorized « jaw crusher 500 ton per hour jaw crusher 700 ton per hour » Get price and support, find the jaw crusher 600 ton per hour Mining & Quarry Plant

Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material Grinding equipment can be classified into to two basic types, crushers and grinders Industrial crushers are the first level of size reducer; further granularizationCrushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons In order to keep the flowsheet simple, and because of the use of the forced feed type of crusher, we can crush small tonnages up to 100 tons per day with a very simple arrangement; using a stationary or Crushing & Screening Plant Design Factors 911 Metallurgist