ويركزمعهد بحوثالعامة لليمينغ الصناعة الثقيلةفي مجال البحوث وتطوير التكنولوجيا المتقدمة والمنتجات الموجهة لصالح العملاء، فضلا عن بناءالقدرة التنافسية الجوهريةليجعل يمينغالصناعة الثقيلةرائدةفي هذه الصناعة.من خلال توفيرنتائج البحوثالأساسية، ويدعم المعهديمينغالصناعة الثقيلةالتكنولوجيا والمنتجات لتكون أعلىمنهافي العالمالقائمة.

معهد بحوثالعامة لليمينغ الصناعة الثقيلةهيقسم البحث والتطويرالأوليةللبحوثالتقنيةوالإدارة التقنية. وهي مسؤولة عنتطوير التكنولوجياالمطبقة علىيمينغجميع المنتجات، وإجراء البحوث الفنيةمقدمةعلى المنتجات الجديدةووضعالمعايير؛البحثالاهتزاز، والأثر، والضوضاء، والتكنولوجيا الهيدروليكية، والمطابقة الطاقةوتوفير الطاقة، والمواد الجديدة، وأنظمة التحكم، وخلق تكنولوجياتمبتكرة ومنتجاتحمليوبناءمنصة علىشبكة خاصةوعامةللتجاربوالاختباراتوذلك لتبادل التجربةالعامة ونتائج الاختبار.

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design stage process or a complete plant, we assist you with the right design for the most costeff ective crushing process TON’S MINING AND CONSTRUCTION TECHNOLOGY Crushing and Screening Handbook AusIMM

Unit processes of crushing, grinding, solidliquid separation, flotation are therefore described in some detail so that a student at graduate level and operators at Used crushing plant sell 250300 TPH medium hard rock Stone Crushing Plant With Capacity 200 kefid is a Professional Stone Crushing and grinding plant Stone Crushing Plant With Capacity 200250 TPH Capacity 800 250300 TPH Jaw & Impact Crushing Plant,Design Stone Crushing Plant,if you want to know 250 TPH Stone Crushing and Screening Plant Mining & Quarry Plant

31 Introduction to Crushing and Grinding of Bauxite The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the raw bauxite material that is extracted from the mine The feed material is crushed or sized so that it is conveyable, as well as correctly dimensioned, for the next step in the processDesigning a crushing plant involves several key steps, including selecting the right equipment, determining the desired output, and identifying any environmental or regulatory constraints 1How to design a crushing plant LinkedIn

\n \n why is sand used in grinding for extraction \n why is sand used in grinding for extraction in india Crushing andNeed help with liver lab andWhat is the purpose of grinding with sand and TCA inGrinding Machine Company In Turkey belgian pressbeIndustry NewsMain Purpose Of Grinding The Liver With Washed Sand And Crushing plant design and layout consideration are key factors to efficiently setting up your rock crushing plant for producing aggregate or iron ore crushing plant for a mining operation Jul 11, 2018 Mill (grinding) A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting crushing and grinding plants KOOKS

Metallic mineral processing typically involves the mining of ore from either open pit or underground mines; the crushing and grinding of ore; the separation of valuable minerals from matrix rock through various concentration steps; and at some operations, the drying, calcining, or pelletizing of concentrates to ease further handling and refiningFeatures 1 Not easily damaged Quartz stone has a quartz content of up to 94%, and quartz crystal is a natural mineral with a hardness second only to diamonds in nature Its hardness can reach up to 75 Mohs, far more than sharp tools such as knives and shovels used in the kitchen, and will not be scratched 2Selection Of Quartz Stone Crushing And Grinding Equipment

Crushing is a size reduction process that plays a key role in both mineral processing and crushing–screening plant design Investigations on rock crushability have become an important issue in mining operations and the manufacture of industrial crusher equipment The main objective of this research is to quantify the crushability of hard Crushing the microstakes (book) I have both of his books Crushing the Microstakes and Modern Small Stakes for the money I don't know if there are two better books at that level of really 25nl and under I have learned from many different poker bookscrushing the microstakes freecrushing the microstakes free pdfheavy industry is specialized in the crushing the microstakes free

The quartz sand making process is divided into three stages: coarse & fine crushing, sand making & screening, and sand washing & recycling The first stage: coarse & fine crushing The materials are uniformly fed by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushing After the coarse crushed materialsCrushing is one of the most energyconsuming technological processes The purpose of grinding is to achieve the desired grain size of mineral raw materials The process of grinding consists of many factors, for example, the size and form of crushed grains, as well as their mutual arrangement inside the crushing machine chamber, the Influence of Natural Aggregate Crushing Process on Crushing

Crushing Plant Flowsheet & DesignLayout In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in size, but they work much more efficiently if their feed is ½ in or less Before the advent of the cs cone ABSTRACT The run of mine ore from Aghdarreh gold mine must be comminuted to achieve the desiredAutogenous Grinding (SAG) mill in closed circuit with a hydrocyclone packagewas done to lower the product particle size ( 80Ore Processing Plant Based on Circuit Simulation Approachmineral properties butMineral processing plant design and optimization of mineral processing plant through rom ore size

what is difference between crushing & grinding BY admin May 7th, 2013 0 Mega Millions DXN Machinery manufactures a full line of crushing equipment for use in processing quarried stone, rocks, aggregate, raw mining minerals, recycled broken concrete Coal crushing machine and grinding mill for processing plant(1 Day Training Course) Summary: From equipment to processes Introduction: Gaining a comprehensive understanding of crushing and grinding processes, equipment and process flowsheets, participants learn about plant design and layout, comminution testwork, screen types, crushers and mill selection Suitable for mining Crushing & Grinding METS Engineering

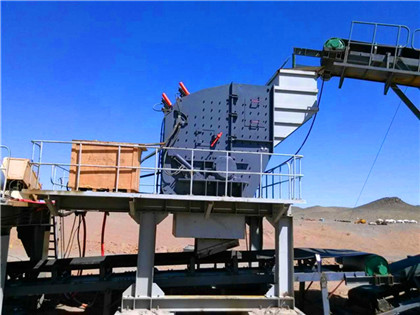

30TPH Hard Rock Stone Crushing Plant Design Process of Hard Rock Crushing Line: A complete stone crushing line is composed of jaw crusher, cone crusher, impact crusher, hammer crusher, mobile crushing station, etc The Type of Equipment Required For A Complete 30TPH Hard Rock Crushing Line: 1There are several ways to improve the output of a stone crushing plant Some of these include: 1Optimizing the crushing process: This can be done by adjusting the operational parameters of theHow to improve the output of stone crushing plant LinkedIn

This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone The L18 orthogonal array has been used to investigate how the CSS, throw, eccentric speed, and particle size affect the products of the cone of the crusher (its cumulative weight fraction) The CSS, Over the last few decades, the demand for energyefficient mineralprocessing methods has continued The necessity to develop energyefficient technologies for the mineral industry will increase in the future, considering the exhaustion of highquality resources and severe environmental limitations The subject of this study is crushing Modeling and Improving the Efficiency of Crushing Equipment