ويركزمعهد بحوثالعامة لليمينغ الصناعة الثقيلةفي مجال البحوث وتطوير التكنولوجيا المتقدمة والمنتجات الموجهة لصالح العملاء، فضلا عن بناءالقدرة التنافسية الجوهريةليجعل يمينغالصناعة الثقيلةرائدةفي هذه الصناعة.من خلال توفيرنتائج البحوثالأساسية، ويدعم المعهديمينغالصناعة الثقيلةالتكنولوجيا والمنتجات لتكون أعلىمنهافي العالمالقائمة.

معهد بحوثالعامة لليمينغ الصناعة الثقيلةهيقسم البحث والتطويرالأوليةللبحوثالتقنيةوالإدارة التقنية. وهي مسؤولة عنتطوير التكنولوجياالمطبقة علىيمينغجميع المنتجات، وإجراء البحوث الفنيةمقدمةعلى المنتجات الجديدةووضعالمعايير؛البحثالاهتزاز، والأثر، والضوضاء، والتكنولوجيا الهيدروليكية، والمطابقة الطاقةوتوفير الطاقة، والمواد الجديدة، وأنظمة التحكم، وخلق تكنولوجياتمبتكرة ومنتجاتحمليوبناءمنصة علىشبكة خاصةوعامةللتجاربوالاختباراتوذلك لتبادل التجربةالعامة ونتائج الاختبار.

Jaw Crusher The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation From: Mineral Processing Design and GRAU JAW CRUSHERS A perfect allround versatile machine capable of crushing all kinds of materials, from soft sedimentary rock to hardest granite or basalt Excellent Jaw Crushers GRAU

Jaw crushers are classified based on the position of the pivoting swing jaw There are three main jaw crusher types: Blake crusher the swing jaw is fixed at the lower position Dodge crusher the swing jaw is fixed at the 5 Common Questions about Jaw Crushers Answered There are many types and styles of crushing equipment Kemper Equipment explains how to choose the right crusher for your operational needs 5 Common Questions about Jaw Crushers Answered

Jaw Crushers Shaft & Bearings The larger eccentricity of pitman shaft provides a motion that pulls the material to the bottom of the jaw plate Crushing Power Wide range of crushing for soft to very hard materials ® C Series™ jaw crushers have proven their reliability in different primary crushing applications, with up to 11 000 jaw crusher installations Read the story behind the C Series™ jaw crushers The story of C Series jaw crushers where it all began?

Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone, marble, shale, gypsum, phosphate, bauxite, aluminum dross, uranium, cryolite, Crusher Reduction Ratio I have mentioned the fact that, as the % of voids in the crushing chamber decreases, the production of fines by attrition increases This is like saying that, as the Crusher Reduction Crusher Reduction Ratio 911 Metallurgist

DOUBLETOGGLE JAW CRUSHER The doubletoggle mechanism, patented in 1858 by Mr E W Blake, remains unrivalled for all units of exceptional power and size Fig 1 is a cross section of an early Blake crusher The power was applied to an eccentric shaft rotated in fixed bearings situated close to the centre of a heavy castiron Jaw crusher The jaw crusher is widely applied to the mining, building materials, chemical, and metallurgical industries It can be used to crush all kinds of ore, rock and other materials whose compressive strength is not more than 320 mpaHow To Choose Cement Crusher? Jaw Crusher, Cone Crusher

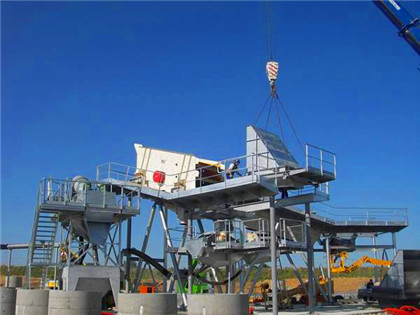

Before assembly, check it carefully, and then use the crane to place the rod bolt slightly lower than its normal position in the crusher Wash the upper and lower bearings of the rod bolt and lubricate them with thin oil, and then install the bearing, main shaft, upper bearing, and upper shell Lifting the rod bolt, then install the bolts andThe PE jaw crusher can process materials with a side length of 100500 mm with the characteristics of large crushing ratio and producing cubic end materials The PE750×1060 jaw crusher is used as the primary crushing equipment for the river pebble with the feed size of 2540 cm The big size of the material must be crushed into differentPE Series Jaw Crusher For Primary Crushing

The core of ® C Series™ jaw crusher is a pinned and bolted, nonwelded frame construction that provides excellent fatigue strength All the frame components are casted using an alloy developed inhouse especially for jaw crushers In addition to solid casting, the crushers’ frame has a cellular, so called honeycomb structure thatCrusher A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore ), so that pieces of differentCrusher

In fact, the jaw crusher flywheel is an essential and crucial component for all mine equipment and in all kinds of crushing equipment, flywheel plays an irreplaceable role in the process of equipment operation, therefore, the jaw crusher flywheel cannot be removedThe main reason for this inefficiency is in the random distribution of forces on the particles inside the crusher With certain simplifications, the theoretical energy efficiency of comminution can be estimated to fall between 5 and 10 % (Legendre & Zevenhoven, 2014) while the measured energy efficiency in actual comminution testing Assessing the energy efficiency of a jaw crusher ScienceDirect

The toggle plate works to transmit power, act as a safety device, and helps to adjust the opening of the jaw crusher It supports the moveable jaw plate and helps to transmit the crushing force to the body The singletoggle jaw crusher is mainly composed of a frame, a jaw plate, two side guard plates, a toggle plate, a flywheel, a shaft, and a regulating device Its frame is cast in sections and then bolted together The casting Single Toggle Jaw Crusher With Unique Benefits

Jaw crusher is suitable for crushing all kinds of ores and rocks whose compressive strength limit is less than 250 mpa It is mainly used as the primary crusher or secondary crusher in cement plant and concrete PC series jaw crusher is new sort of rock crusher with higher efficiency They are the most productive and costefficient jaw crushers for any primary crushing application They are able to crush all kinds of hard and abrasive rock and mineral ore In past few years, Powerups engineers have been working to improve the wear life of jaw What Is Jaw Crusher Powerups Crusher

PE Jaw Crusher Jaw crusher is used for crushing all kinds of ores and rocks with compressive strength below 320MPa It is generally used for primary crushing of materials The machine is widely used in mining, building materials, metallurgy, electric power, water conservancy, transportation and many other fields 0086371The jaw crusher of eastman can crush all kinds of materials with compressive strength not exceeding 250 MPa It is widely used for the primary crushing of various ores and rocks in various fields such as mining, smelting, building materials, highway, railway, water conservancy and chemical industry, such as limestone, iron ore, 7 Differences of Jaw Crusher Eastman Rock Crusher

Jaw crushers are the archetypal crusher used for the dismantling of rock and stone, with a quarry jaw crusher you are able to crush all kinds of materials to various sizes depending on your requirements The movable jaw applies force on the rock and forces it against the stationary plate, the rocks then remain between the jaws until the material is small With the features of smart structure and excellent performance, JC jaw crusher is suitable for crushing all kinds of hard and abrasive rock and mineral ore In order to meet the needs of different working conditions from the customers, JC jaw crusher can apply modular bolt connecting frame without weldingJC Series Jaw Crusher ATAIRAC ENGINEERED PRODUCTS INC

Here are some of the main types: Blake jaw crusher: This is one of the earliest and most common types of jaw crushers It has a fixed jaw and a movable jaw pivoted at the top The crushing chamberThese are important questions that need answering when choosing the right machine for your application Output size This determines what type of products may be produced from the crusher A jawConsiderations when choosing a concrete crusher LinkedIn