ويركزمعهد بحوثالعامة لليمينغ الصناعة الثقيلةفي مجال البحوث وتطوير التكنولوجيا المتقدمة والمنتجات الموجهة لصالح العملاء، فضلا عن بناءالقدرة التنافسية الجوهريةليجعل يمينغالصناعة الثقيلةرائدةفي هذه الصناعة.من خلال توفيرنتائج البحوثالأساسية، ويدعم المعهديمينغالصناعة الثقيلةالتكنولوجيا والمنتجات لتكون أعلىمنهافي العالمالقائمة.

معهد بحوثالعامة لليمينغ الصناعة الثقيلةهيقسم البحث والتطويرالأوليةللبحوثالتقنيةوالإدارة التقنية. وهي مسؤولة عنتطوير التكنولوجياالمطبقة علىيمينغجميع المنتجات، وإجراء البحوث الفنيةمقدمةعلى المنتجات الجديدةووضعالمعايير؛البحثالاهتزاز، والأثر، والضوضاء، والتكنولوجيا الهيدروليكية، والمطابقة الطاقةوتوفير الطاقة، والمواد الجديدة، وأنظمة التحكم، وخلق تكنولوجياتمبتكرة ومنتجاتحمليوبناءمنصة علىشبكة خاصةوعامةللتجاربوالاختباراتوذلك لتبادل التجربةالعامة ونتائج الاختبار.

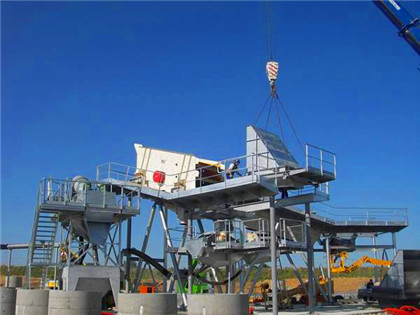

A toggle plate is a mechanical component that connects the movable jaw to the rest of the jaw crusher It acts as a safety device in case of an overload or shock loading When an object is too hard or too Problem 1: Broken toggle plate A broken toggle plate is a serious problem that requires immediate attention The first step is to shut down the jaw crusher and ensure that all power sources are Problems with Toggle Plates in Jaw Crushers and How

There are two main types of toggle plates used in jaw crushers: single toggle and double toggle Single toggle plates are simpler and less costly and have an oscillating jaw that pivots at the bottom of This study reports on the design optimisation of the swinging jaw crusher plate Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

The present research work deals with the kinematic analysis of the swing jaw plate of a single toggle jaw crusher Findings During the analysis, the system is [Show full abstract] laboratory doubletoggle jaw crusher The obtained results were compared to the energy associated to rock crushing by threeangular tips (PDF) Selected Design Issues of Toggle Plate Selection on the

PDF A jaw crusher is a kind of size reduction machine which is widely used in mineral, aggregates and metallurgy fields The performance of jaw Find, read and cite all the research you needThis study shows that the jaw crusher plate geometry influences the flow stress and deformation behaviour during the crushing process The findings from this Optimisation of the swinging jaw design for a single toggle jaw

For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54” across the width of the two jaw dies HSeries Jaw Crushers still use a toggle plate that has the dual purpose of transferring the crushing action and a fuse to protect the crusher's major componentstoggle plate of jaw crusher pe150x250,pe250x400,pe400x600,pe600x900,pex250 x 1200Jaw Crusher BADJA TEHNIK MACHINERY

Precision Crushers & Spares is a manufacturer and supplier of jaw crusher spare & wear parts such as jaw plate, fixed jaw plate, cheek plate & toggle plate etc +971 (0)9 228 2209 +971 (0)9 228 2210 The toggle plate of a jaw crusher can break due to excessive stress or impact from an object Additionally, the jaws may become misaligned due to wear and tear over time, resulting in a breakageWhat causes the jaw crusher toggle plate to break? LinkedIn

Double Toggle Jaw Crusher: Outlet gap can be varied easily by add OR remove mild steel plates between toggle plate and the main body Technical Specification: Model Output (Ton/Hr) Out let gap (MM) RPM Motor Feed size Max(MM) Inlet Size (MM) 60 50 40 25 20 15 PJC12x710 8 6300 15 140 300 x 175 Request CallbackAlso, check components significant level by different plots such as normal probability plot, Pareto plot and contour plot Jaw plate has the significant component amongst all the components R 2 value obtained is 9898 % for jaw crusher, 9887 % for back toggle plate, 9283 % for chute liner plate, 9964 % for jaw plate and 9312 % for Failure analysis of jaw crusher and its components using ANOVA

Established as a Partnership Firm in the year 2003 at Jhansi (Uttar Pradesh,India),we"Swastik Iron Foundry" are a leading Manufacturer and Supplier of a wide range of Jaw Plate, Wire Mesh Jali etc we, Swastik Iron Foundry, are engaged in Manufacturing superior quality Industrial Crusher Parts Our product range includes All The toggle plate works to transmit power, act as a safety device, and helps to adjust the opening of the jaw crusher It supports the moveable jaw plate and helps to transmit the crushing force to the body frame If a piece of material is put into the jaw crusher that cannot be crushed, the toggle plate automatically disconnects, Parts of a Jaw Crusher Wagner Used Equipment

Fig3 shows the configuration of the jaw crusher and geometrical and operation parameters are given in Table 1 Jaw crusher mainly, consist of moving jaw, eccentric shaft, flywheel and toggle plate The jaw has specific motion to break feed material by the means of eccentric shaft while jaw width is 1100 mm, gaps from upper side is 650 mmFig 7 Contour plot of a jaw crusher, b back toggle plate, c chute liner plate, d jaw plate and e and tie rod Author's personal copy J Braz Soc Mech Sci EngFailure analysis of jaw crusher and its components using ANOVA

On the insides of the jaw crusher, cheek plates serve as additional wear parts to protect the crusher mainframe The two jaw plates are arranged in a Vshape, narrowing the space from top to bottom The nip angle is the angle formed by the V An eccentric shaft passes through the top of the jaw stock and pivots around a toggle plate Wear parts include: Jaw Plates Cheek Plates Wedges Toggles Toggle Seats Unicast proprietary alloys and innovative designs result in long wear life compared to other OEM replacements Unicast jaw crusher wear Replacement Jaw Plates, Cheek Plates, Wedges

Jaw crusher with toggle plate tensioning feature and associated method of crushing rock Applications Claiming Priority (3) Application Number Priority Date Filing Date Title; US11/079,352: : AUA AUB2 (en) : : Jawtype rockCheck tightness of tension rod daily 3 Examine cheek plates, jaw dies and jaw die extensions for wear every several days at first, every week thereafter Reverse or replace when necessary 4 Examine toggle bearing, toggle plate and toggle block for wear at least once a month; replace when necessary 07/03/08 37 Jawmanual 07 03 08 Locked PDF PDF Bearing Scribd

A Jaw Crusher Toggle Plate and tension rods hold the read more Varshini Equipments Madukkarai, Coimbatore No 13/1C, Eachanari To Madukkarai Road, Madukkara PO, Madukkarai, Coimbatore , Dist Coimbatore, Tamil Nadu TrustSEAL Verified View Mobile Number Call +91singletoggle jaw crusher is directly proportional to the area of the charging opening described by F Taggart in 1927 [16]: Q =930,⋅L⋅B where L and B are the length and the width of the jaw crusher charging opening, m Taggart formula takes into account just two structural settings of the crusher However, it is quiteRIVLQJOH WRJJOHMDZ FUXVKHU

TON Jaw crushers come with everything you need for plugandplay primary crushing operations Each jaw crusher comes with feed hopper, feed hopper interface, drive and subframe with vbelt guard and motor bracket, our unique guarding retraction arrangement and toggle plate stop The wide range of jaw platesIt is used for the crushing of large blocks of hard and abrasive materials There are eleven main components of a jaw crusher are presented below 1 Feed Chute 2 Drive Flywheel 3 VbeltsPart 02 Jaw Crusher LinkedIn

Jaw plate kinematical analysis for single toggle jaw crusher design J Cao, Xingfu Rong, S Yang Published 2006 Materials Science Jaw crusher is a kind of size reduction machine which is widely used in the mining and aggregates industry The interaction between jaw plates and material particles brings the inevitable and serious wear to theJaw Crusher / Toggle Plate PE 500 x 750 Rp4100000 Jakarta Barat Delia per spring Ad Jaw Crusher 65 X 8 Inch Rp55000000 Kab Bandung Barat materialtestindo Ad Harga Mesin Jaw Crusher 400 x 600 Bekasi Rp185000 Harga Mesin Penghancur Pemecah Batu Jaw Stone Crusher 250x400mm AKS PS2540Jual Jaw Crusher Terlengkap Harga Terbaru November 2023